EXECUTIVE SUMMARY

Good Enough for a Post IEEE 1584-2018 Risk Assessment?

- The IEEE 1584-2018 guide raises risk analysis questions for organizations.

- IEEE 1584-2018 calculates the impact of arc-flash differently than the 2002 version.

- New variables in IEEE 1584-2018 arc-flash studies affect arcing current calculations and protective device response time.

- Time is an important factor when it comes to incident energy.

- The constant energy boundary is a tool that organizations can use to evaluate whether their previous PPE choices are adequate considering what a 2018 study might predict.

- This analysis may clarify whether existing PPE selections are adequate or whether more attention is required.

Context

Adapting IEEE 1584-2002 Arc Flash Study Results to a Post IEEE 1584-2018 Risk Assessment

This presentation is a based on a paper presented at the IEEE 2020 Electrical Safety Workshop in March 2020.

Adapting IEEE 1584-2002 Arc Flash Study Results to a Post IEEE 1584-2018 Risk Assessment

This presentation is a based on a paper presented at the IEEE 2020 Electrical Safety Workshop in March 2020.

Key Takeaways

IEEE 1584-2018 is prompting organizations to reconsider their old arc-flash studies and PPE selections. Common questions include:

Old Arc-Flash Studies

What should organizations do with their old arc-flash studies and PPE selections?

Continued Use of 2002 Arc-Flash

Is it ok to continue using 2002 arc-flash studies and PPE selections until the organization conducts a 2018 arc-flash study?

Ignoring

IEEE 1584-2018

What are the risk assessment and control implications of ignoring IEEE 1584-2018?

Adequate PPE

for Workers

Based on the new science, do workers have adequate PPE for the potential severity of an arc-flash event?

Old Arc-Flash Studies

What should organizations do with their old arc-flash studies and PPE selections?

Continued Use of 2002 Arc-Flash

Is it ok to continue using 2002 arc-flash studies and PPE selections until the organization conducts a 2018 arc-flash study?

Ignoring

IEEE 1584-2018

What are the risk assessment and control implications of ignoring IEEE 1584-2018?

Adequate PPE

for Workers

Based on the new science, do workers have adequate PPE for the potential severity of an arc-flash event?

Old Arc-Flash Studies

What should organizations do with their old arc-flash studies and PPE selections?

Continued Use of 2002 Arc-Flash

Is it ok to continue using 2002 arc-flash studies and PPE selections until the organization conducts a 2018 arc-flash study?

Ignoring

IEEE 1584-2018

What are the risk assessment and control implications of ignoring IEEE 1584-2018?

Adequate PPE

for Workers

Based on the new science, do workers have adequate PPE for the potential severity of an arc-flash event?

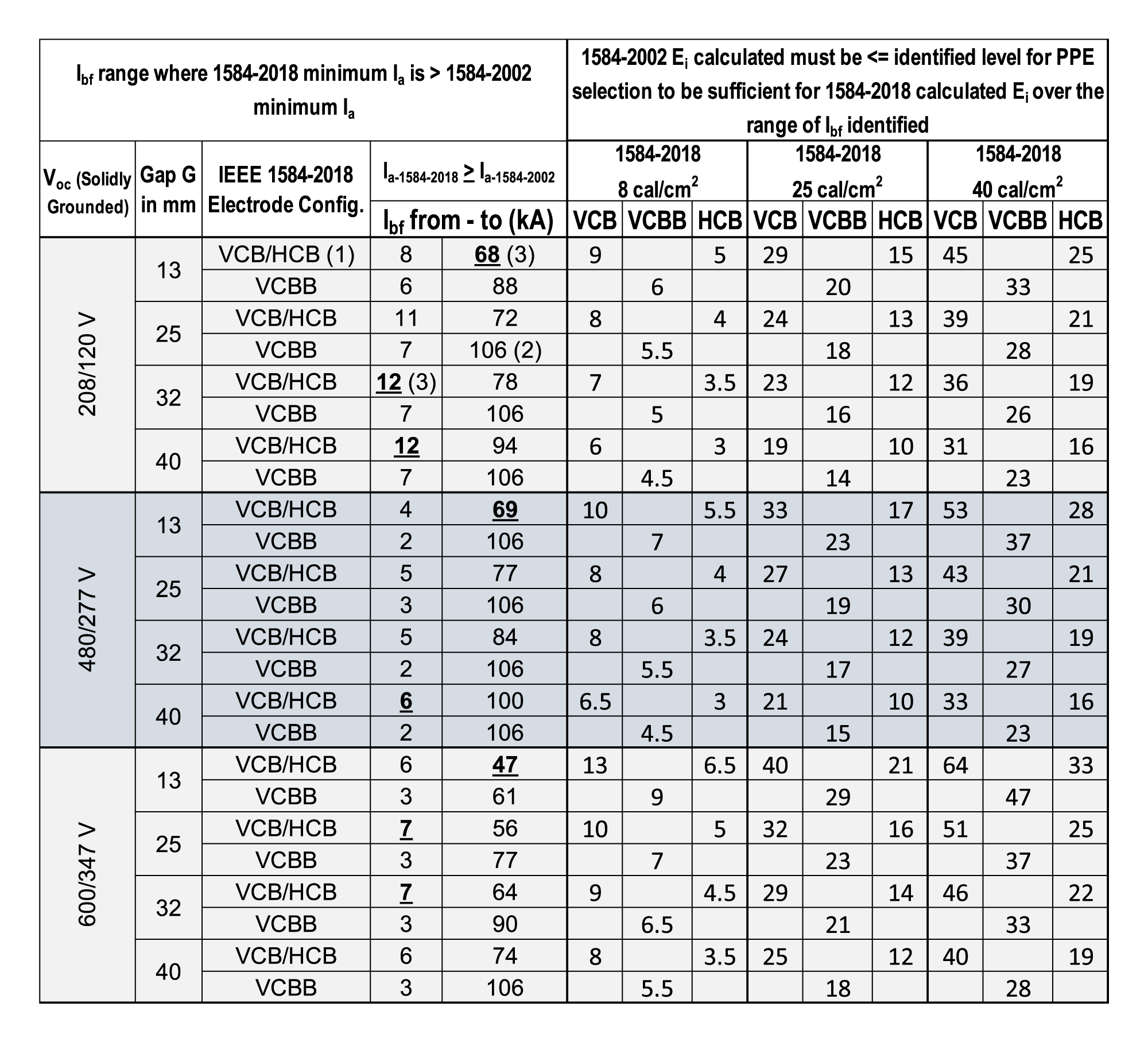

In the region between the two vertical black lines in Figure 8, the data is comparable. The vertical lines bound the range of bolted fault current where the 2018 arcing current will be larger than the 2002 arcing current calculations. One can assume that the time, gap, working distance, and enclosure variables are the same. Therefore, from the graph before, since we know the OPCD protected at the black line or faster, the incident energy for VCB exposure predicted with the 2018 model will be less.

As shown in Figure 9, for VCBB, the incident energy depends on the exact bolted fault current. And for HCB, it is always worse. However, this assumes that the incident energy target performance is the same for the 2002 and the 2018 arc-flash studies.

In reality, there is a high likelihood that 2002 arc-flash studies resulted in PPE selections that could accommodate more incident energy than the actual exposure. Usually the PPE level selected or recommended is greater than the calculated incident energy. Typical values of PPE may be 8, 25, or 40 calories. The open question is whether the margin is big enough to cover the difference between the 2002 arc-flash calculations and what calculations using the new 2018 model would predict. As outlined in Figure 10, using the right graphs can help answer this question.

Notes

≥2.7kV 1584-2018 always yields lower Ia

- VCB & HCB have similar Ia so they are grouped in this table.

- Ia not calculated for > 106 kA Ibf.

- Bolded numbers are the highest minimum & lowest maximum in the voltage range

The method is solely intended to provide an estimating tool that may be useful in the process of risk analyses associated with evaluating if PPE has a high enough arc rating, under certain identified limited conditions, to exceed the incident energy that may be calculated by an Arc Flash study performed using IEEE 1584-2018 under the same identified limited conditions.

Additional Resources

This presentation is a based on a paper presented at the IEEE 2020 Electrical Safety Workshop in March 2020.