EXECUTIVE SUMMARY

Labor Overruns are Costly: Understanding Labor is the Key to Estimating Accuracy

- Accurate labor hour estimates decrease costly labor overruns.

- A clear understanding of labor units and columns is key to good estimation.

- Installation labor factors increase or decrease labor units based on difficulty.

- Project labor factors identify conditions that negatively impact productivity.

- Focus on projects and categories that commonly impact estimates.

- Along with proper estimating, ABB empower helps improve productivity.

Context

Labor Overruns Are Costly

Key Takeaways

- Not including enough labor hours in the estimate

- A failure to apply installation labor factors; difficulty can increase the estimate

- A failure to calculate project labor factors; difficulty can increase the estimate

- Poor project management

- Poor labor productivity

Accurately estimating labor hours and keeping focus on the factors that make a difference in estimation are central to decreasing overruns.

A clear understanding of labor units and columns is key to good estimation.

TEST YOUR KNOWLEDGE

- Slab

- Trench – Single runs

- Trench – Multiple runs

- Parallel runs

- Metal stud: Increase of 25% to labor unit

- Masonry: Increase of 100% or more to labor unit

- Vertical runs

- Exposed above normal heights; increase depends on exposed height on lift

- Slab

- Trench – Single runs

- Trench – Multiple runs

- Parallel runs

- Metal stud: Increase of 25% to labor unit

- Masonry: Increase of 100% or more to labor unit

- Vertical runs

- Exposed above normal heights; increase depends on exposed height on lift

- Labor hours are added to the direct labor hours total.

- Percentages will differ in various markets and geographic locations, and estimators need to understand their areas. What is application on the West Coast may not be applicable on the East Coast.

- Labor factor percentage adjustments are cumulative throughout the project.

- Labor factors are addressed in the bid summarization.

Focus on projects and categories that commonly impact estimates.

Project type

Each type of project includes a core set of needs, which should be focused on during estimation. For example:

- Commercial work: 60%-80% branch wiring

- Retail space: 80%-90% branch wiring

- Water treatment: 85% site power, distribution, feeders, and generation

- Gas & oil: 50%-60% tray and tray cable

Labor categories (labor cost codes)

Focus on the costliest labor categories. For almost any project, the top three most common costs, making up 82% of the combined labor percentage, are:

- Conduit – fittings – boxes (54%)

- Wire pulling (19%)

- Fixtures (8%)

Systems

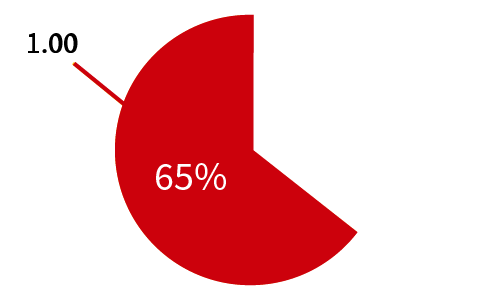

To understand the impact to the estimate, focus on the largest systems. For almost any project, about 65% of the total combined labor percentage comes from the following four systems:

- Lighting (26%)

- Site lighting (16%)

- Branch wiring (13%)

- Data (9%)

Material categories

Focus on the largest material categories when developing an estimate. For almost any project, 84% of total material costs are attributed to two categories:

- Conduit – fittings (23%)

- Wire & cable (61%)

Largest cost items