EXECUTIVE SUMMARY

Electrical Contractors and BIM:

What It Can Do for You

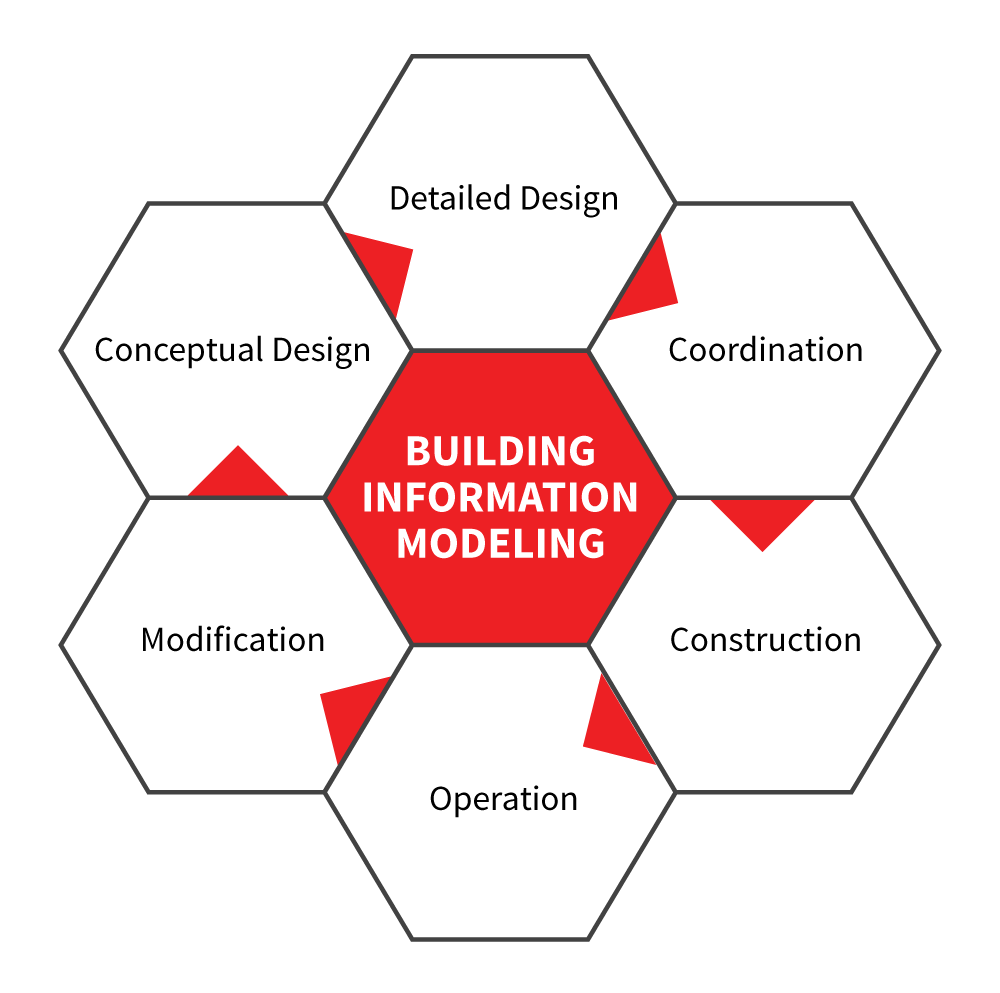

- BIM streamlines project execution, from concept to operation and modification.

- Conceptional design: Spatial layout and visualization in BIM.

- Detailed design: Systems, estimation, and quantities in BIM.

- Coordination: Identifying and resolving conflicts in BIM.

- Construction: Pre-fab materials and BIM.

- Operation: Repair and maintenance support in BIM.

- Using ABB eFab pre-configured assemblies in AutoDesk Revit.

Context

Electrical Contractors and BIM

How BIM is used throughout the building proceess

Key Takeaways

AEC professionals can use BIM software throughout the complete building process.

Conceptual design

focuses on spatial layout visualization and design options, ensuring everything fits together at a high level.

Detailed design

dives into the specific system that will be put in place. This phase incudes estimation of time and resources and determining quantities of materials needed, and allows for project simulation.

Coordination

makes sure there are no conflicts between the different trades interacting in the building or with the materials. This phase includes deviations and constructability.

Construction

is where logistics and processes are identified, and where pre-fabricated (pre-fab) items are included to simplify the project.

Operation

moves the project in the owner's hands. This phase includes facility management, repair, and maintenance.

Modification

focuses on changes that need to be made to the building at a later date, including retrofitting, recycling, and replacement.

Conceptual design

focuses on spatial layout visualization and design options, ensuring everything fits together at a high level.

Detailed design

dives into the specific system that will be put in place. This phase incudes estimation of time and resources and determining quantities of materials needed, and allows for project simulation.

Coordination

makes sure there are no conflicts between the different trades interacting in the building or with the materials. This phase includes deviations and constructability.

Construction

is where logistics and processes are identified, and where pre-fabricated (pre-fab) items are included to simplify the project.

Operation

moves the project in the owner's hands. This phase includes facility management, repair, and maintenance.

Modification

focuses on changes that need to be made to the building at a later date, including retrofitting, recycling, and replacement.

Conceptional design: Spatial layout and visualization in BIM.

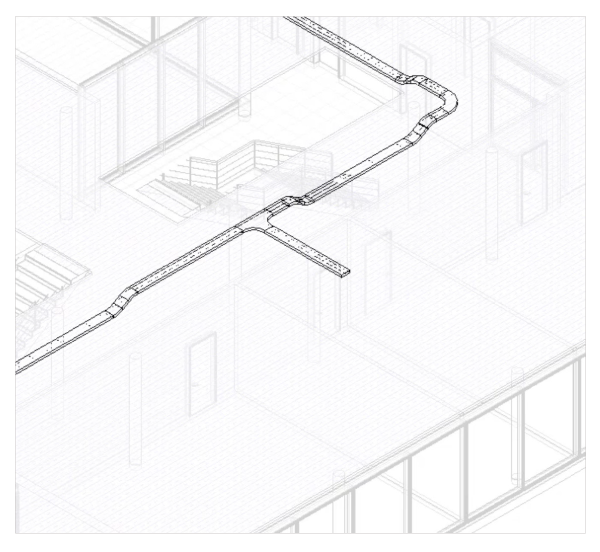

Detailed design: Systems, estimation, and quantities in BIM.

Conceptual layouts are enhanced during the detailed design phase. Information such as manufacturer and part are added to the layout. During this phase, every element in the project is scheduled, and accurate counts are given across the project for each element type. Schedules can be:

- Generic, such as a “cable tray in the project,” or

- Granular, such as “cable tray runs on level 1 greater than 3 feet, from a specific manufacturer.”

Checks can also be run on the schedule to identify problems, such as when an item does not meet the manufacturer specifications, meaning it can’t be produced. Identifying these problems up front saves both time and money, as changes are easier and less costly to make in the design phase.

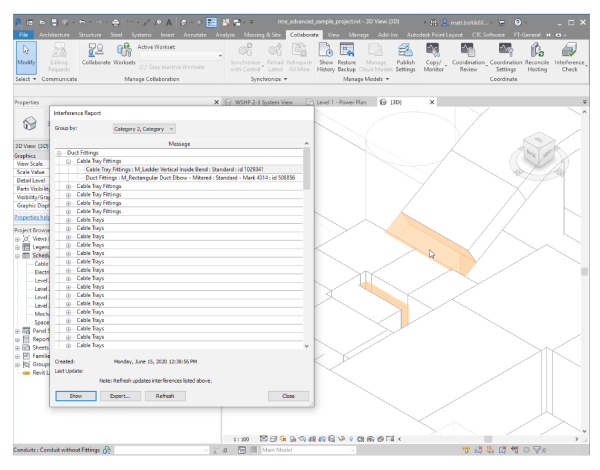

Coordination: Identifying and resolving conflicts in BIM.

BIM identifies design conflicts in real time within the software, enabling users to identify and resolve conflicts before they impact project schedules and budgets. For example, in Figure 3 below a ductwork layout is copied from one floor of a building to the next, but one of the floors has a different height. BIM identifies that conflict so the ductwork can be adjusted for that floor in the design phase.

BIM catches conflicts, enabling low-impact resolution during design

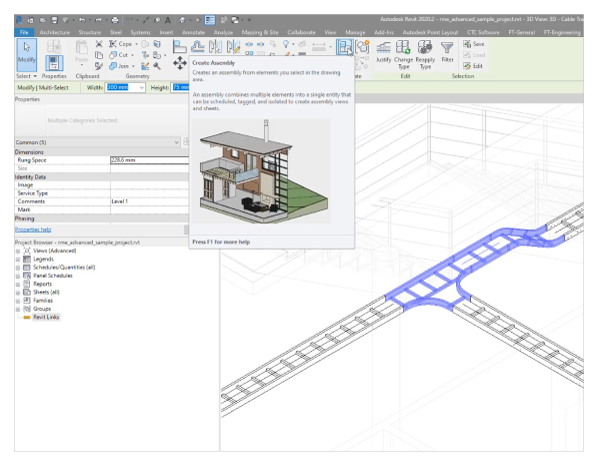

Construction: Pre-fab materials and BIM.

Assemblies allow content to be placed, tagged, and scheduled as a single item, rather than a disparate set of components. Views and schedules of parts are automatically generated for each assembly.

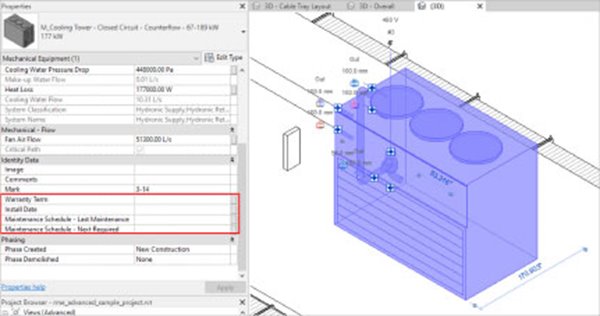

Operation: Repair and maintenance support in BIM.

BIM designs can store custom parameters, such as warranty terms, installation dates, maintenance schedules, and last and next maintenance dates. Because the information is custom, owners can determine what information they want to retain in the product.

ABB eFab Revit families can be downloaded from the ABB website. These families are easy to load, easy to place and align in the plan for precision coordination, and offer an accurate three-dimensional representation of the assembly.